Work produced alongside Nadia DeFazio, Lachlan Palmer, and Oscar Howard.

A speculative solution to the climatic conditions of 2040.

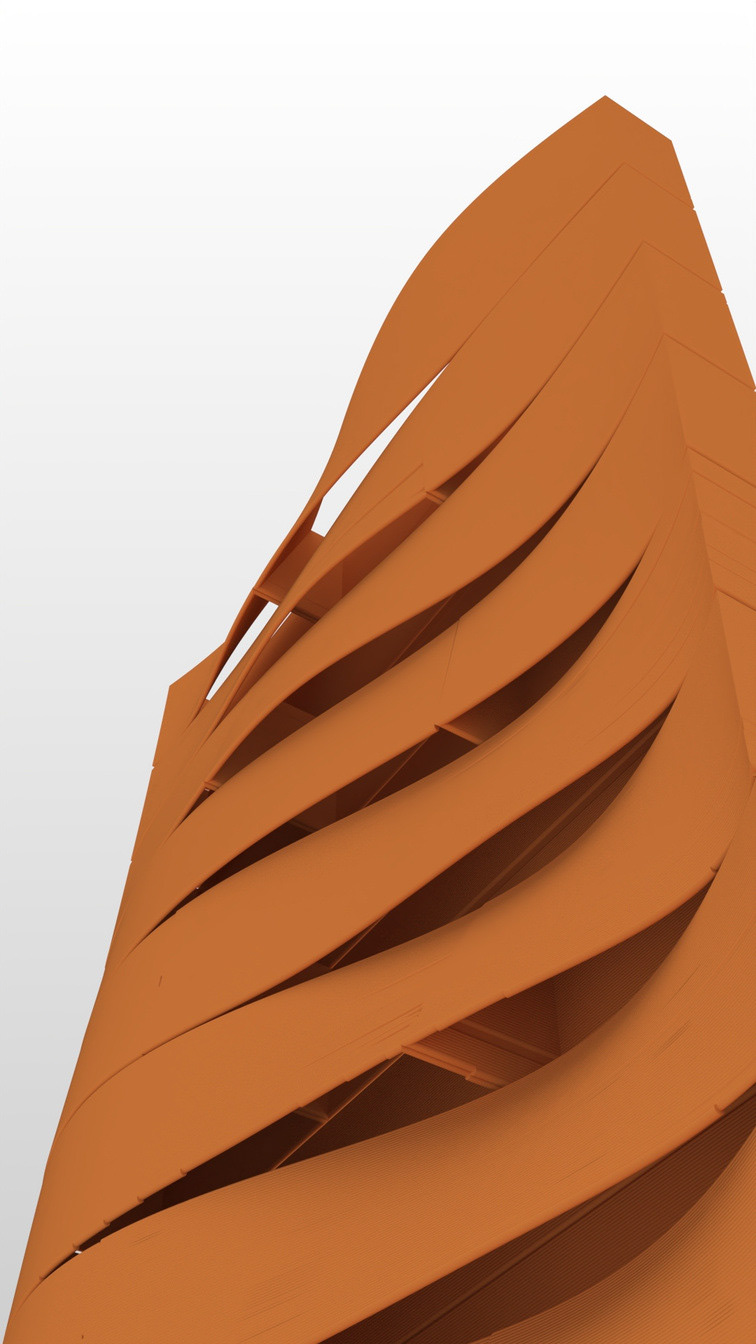

This 3D printed ceramic structure provides heat refuge to the residents of Melbourne's inner north using the natural evaporative cooling effects of terracotta.

This 3D printed ceramic structure provides heat refuge to the residents of Melbourne's inner north using the natural evaporative cooling effects of terracotta.

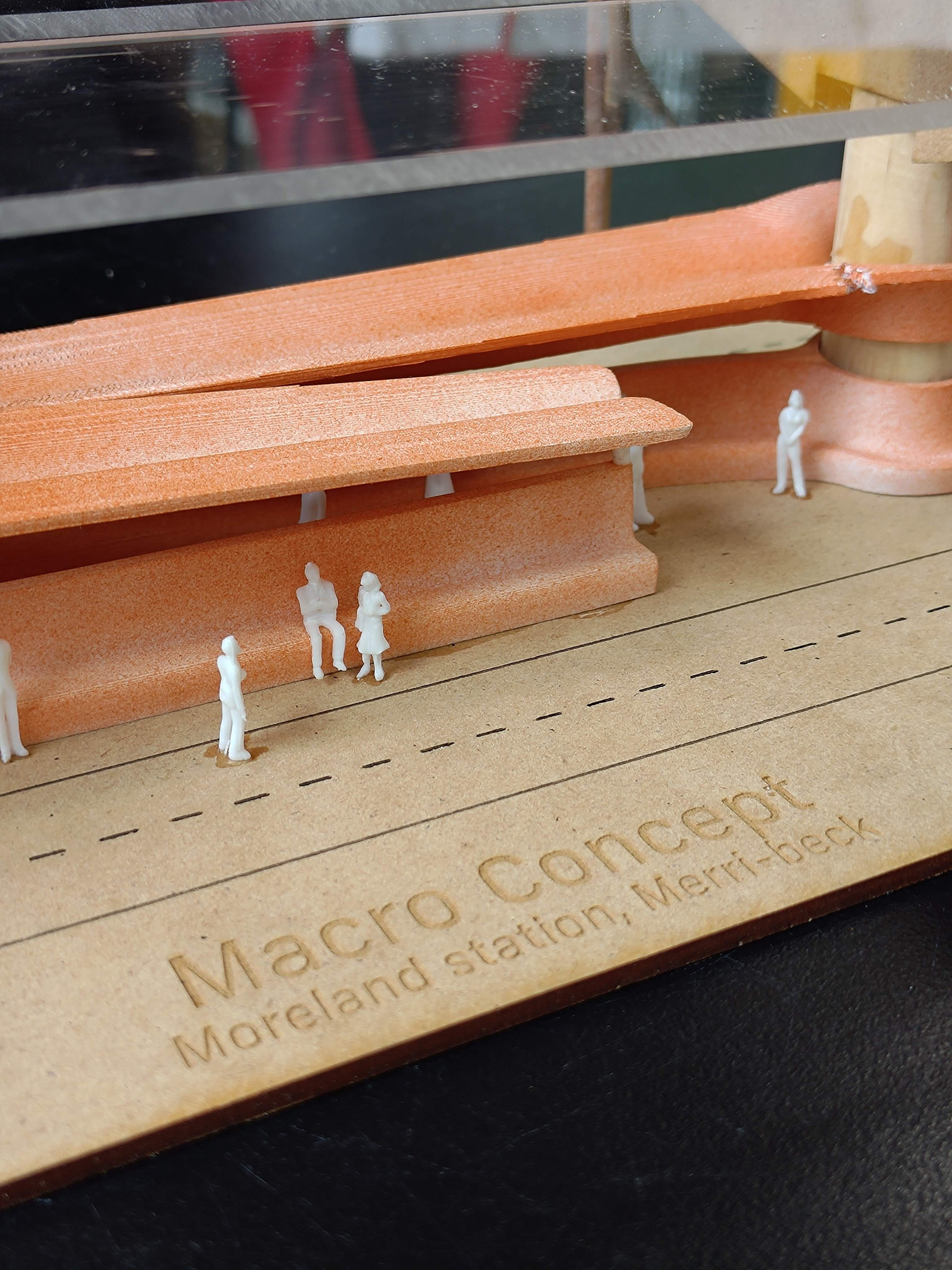

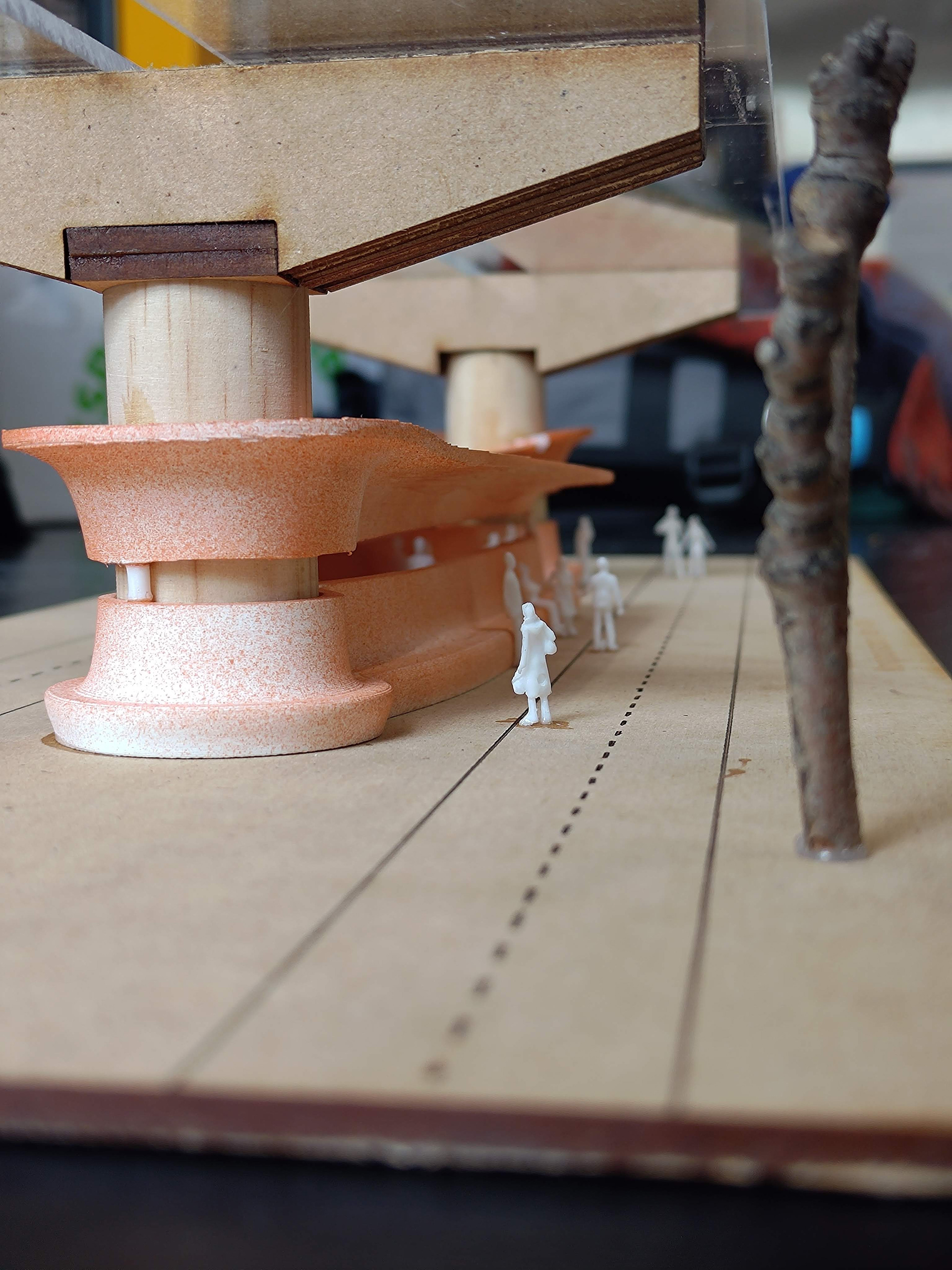

A site was chosen, underneath an elevated section of rail near Moreland station, Coburg.

The directionality of the site's pedestrian and cycle paths informed our design, along with a desire to mimic the natural flow of water.

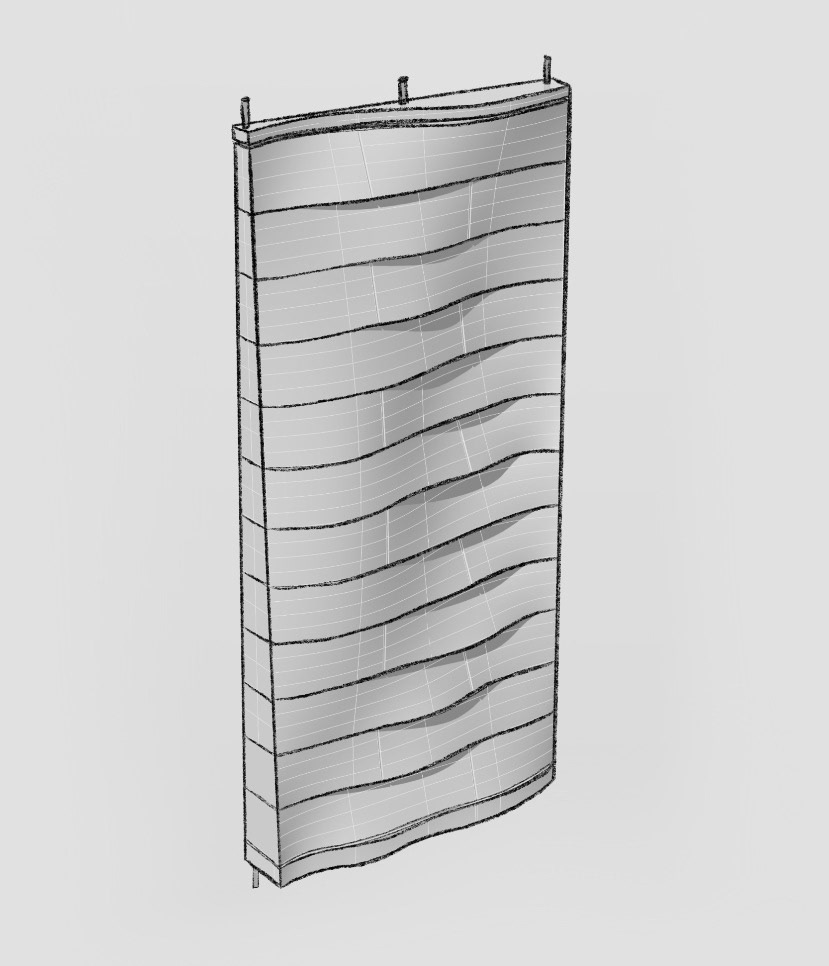

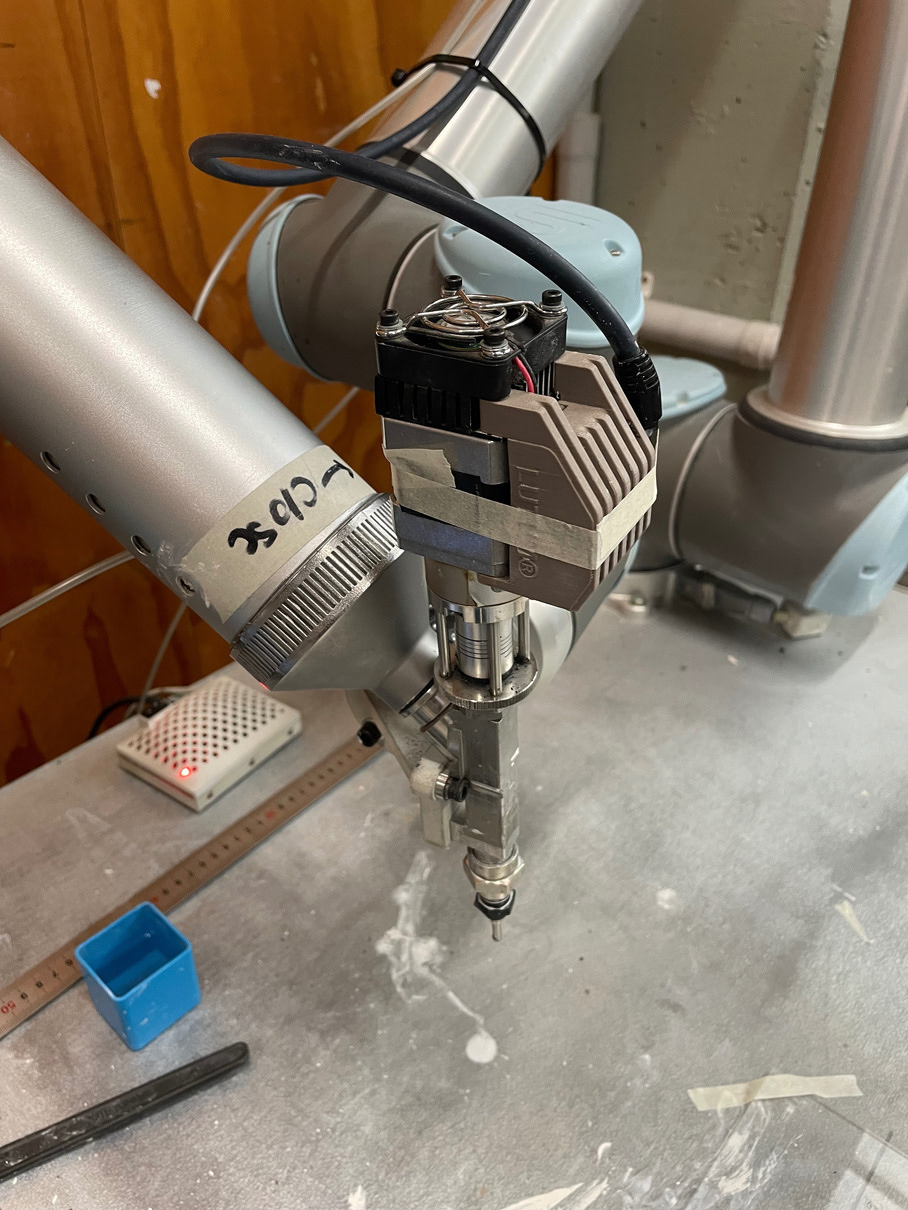

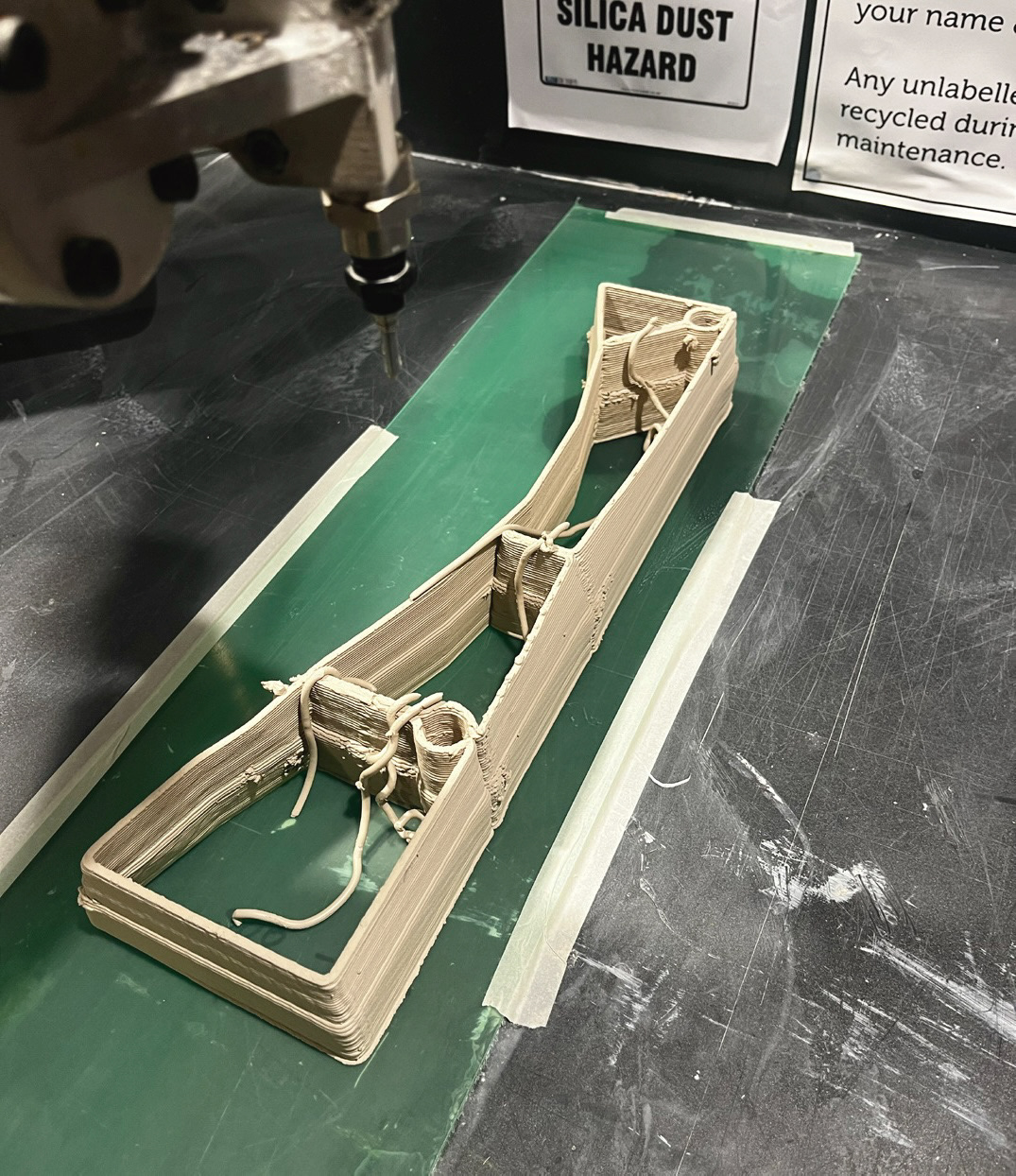

The structure is formed using thousands of unique 3D printed terracotta bricks. As a proof of concept, a 600x1200mm 1:1 scale section of wall was drawn and prepared for printing.

The section was split into 24 bricks, each uniquely shaped and contributing to the larger structure's parametric design.

A large section of the project was dedicated to the execution of this prototype - learning to use the UR-10 robotic arm for printing, preparing ceramics for firing, and assembly of the wall section.

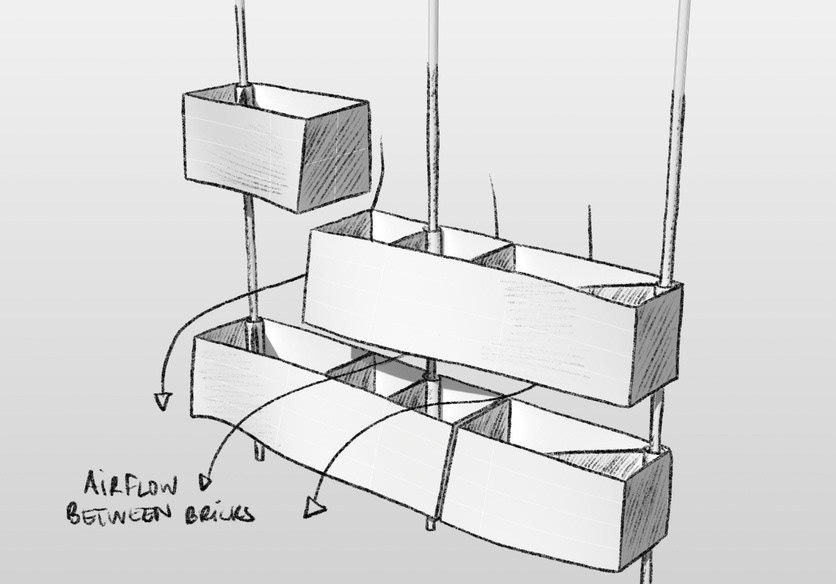

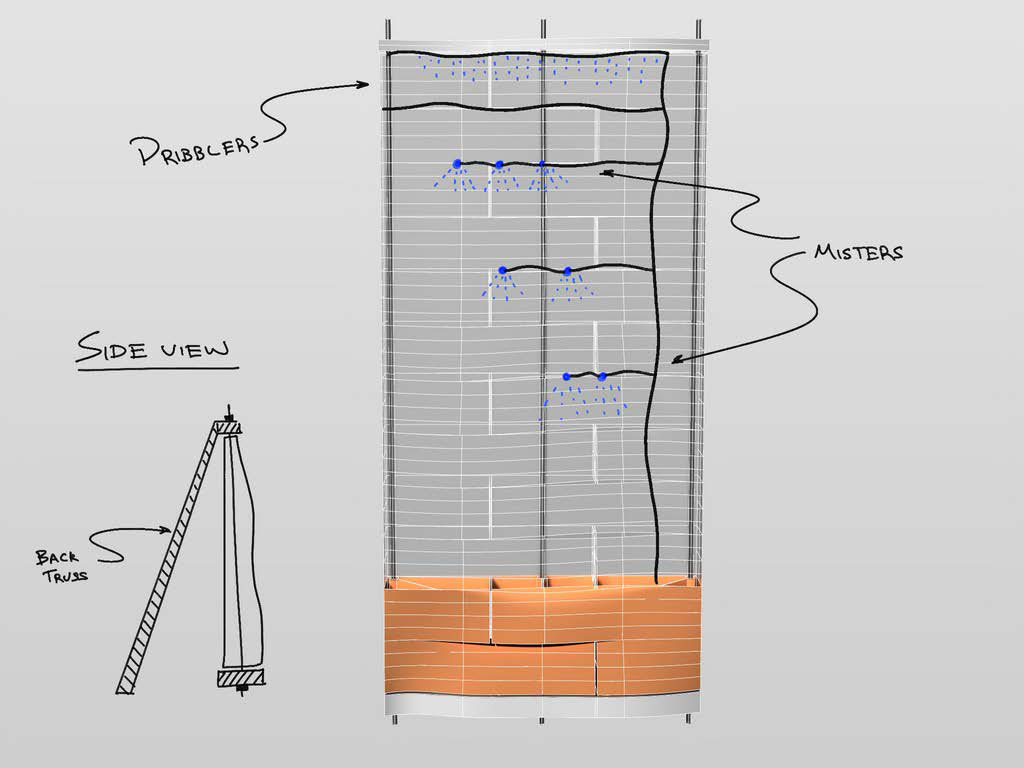

The wall’s louvres and porous surface encourage airflow and water

movement, passively cooling the air through evaporative processes, generating a comfortable micro-climate beneath the rail line.

movement, passively cooling the air through evaporative processes, generating a comfortable micro-climate beneath the rail line.

By integrating passive cooling and renewable water use, our proposal demonstrates how design can

respond to environmental pressures while creating inviting, human-centred spaces for future cities with under-utilised public space.

respond to environmental pressures while creating inviting, human-centred spaces for future cities with under-utilised public space.

This project challenged us to think holistically, to maintain

our design intent through the complicated execution of fabrication, and to

respond to the constraints and strengths presented by the printing process.

our design intent through the complicated execution of fabrication, and to

respond to the constraints and strengths presented by the printing process.