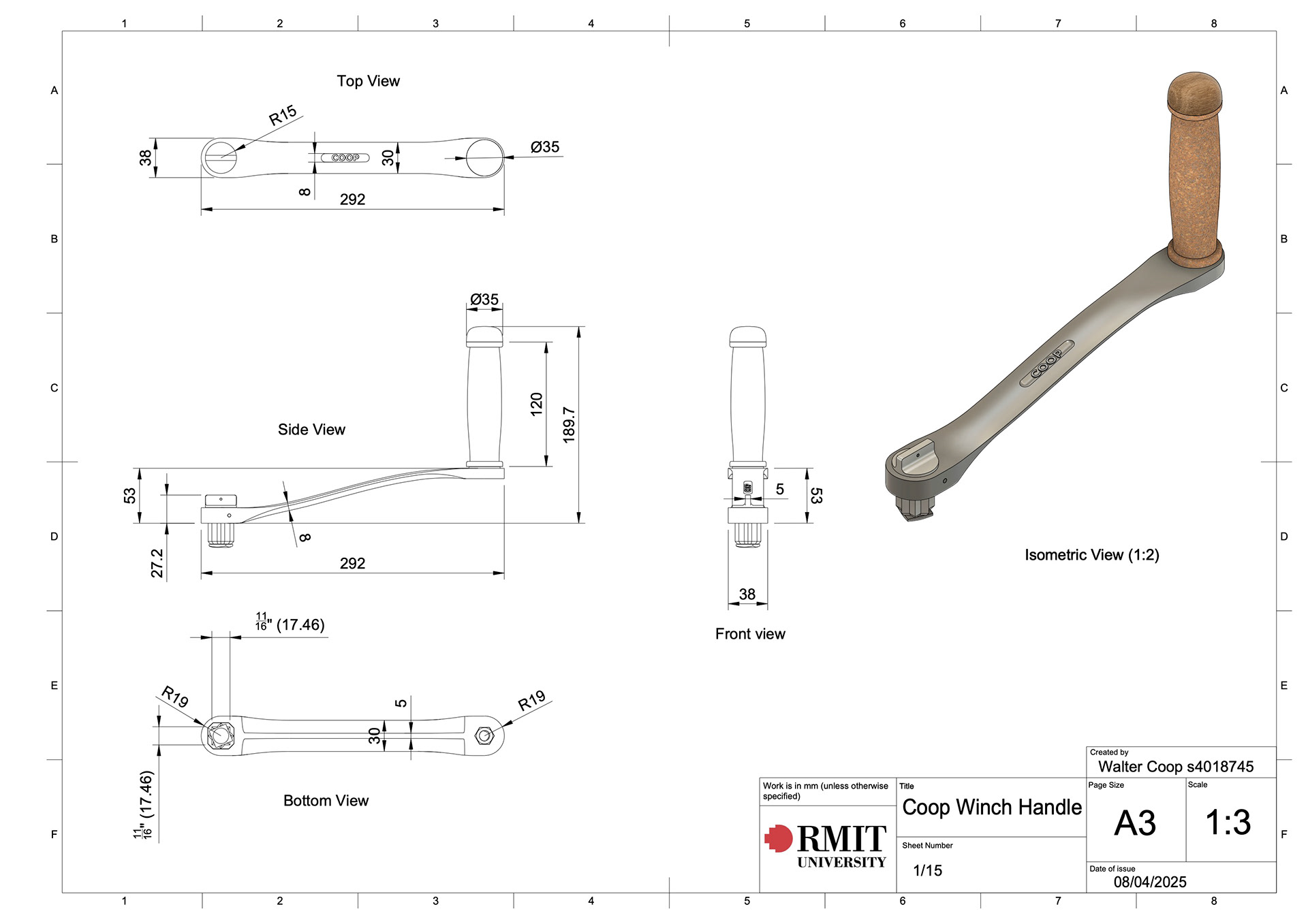

An opportunity to investigate advanced methods of prototyping and fabrication, this project saw me design and produce a new take on the sailor's winch handle.

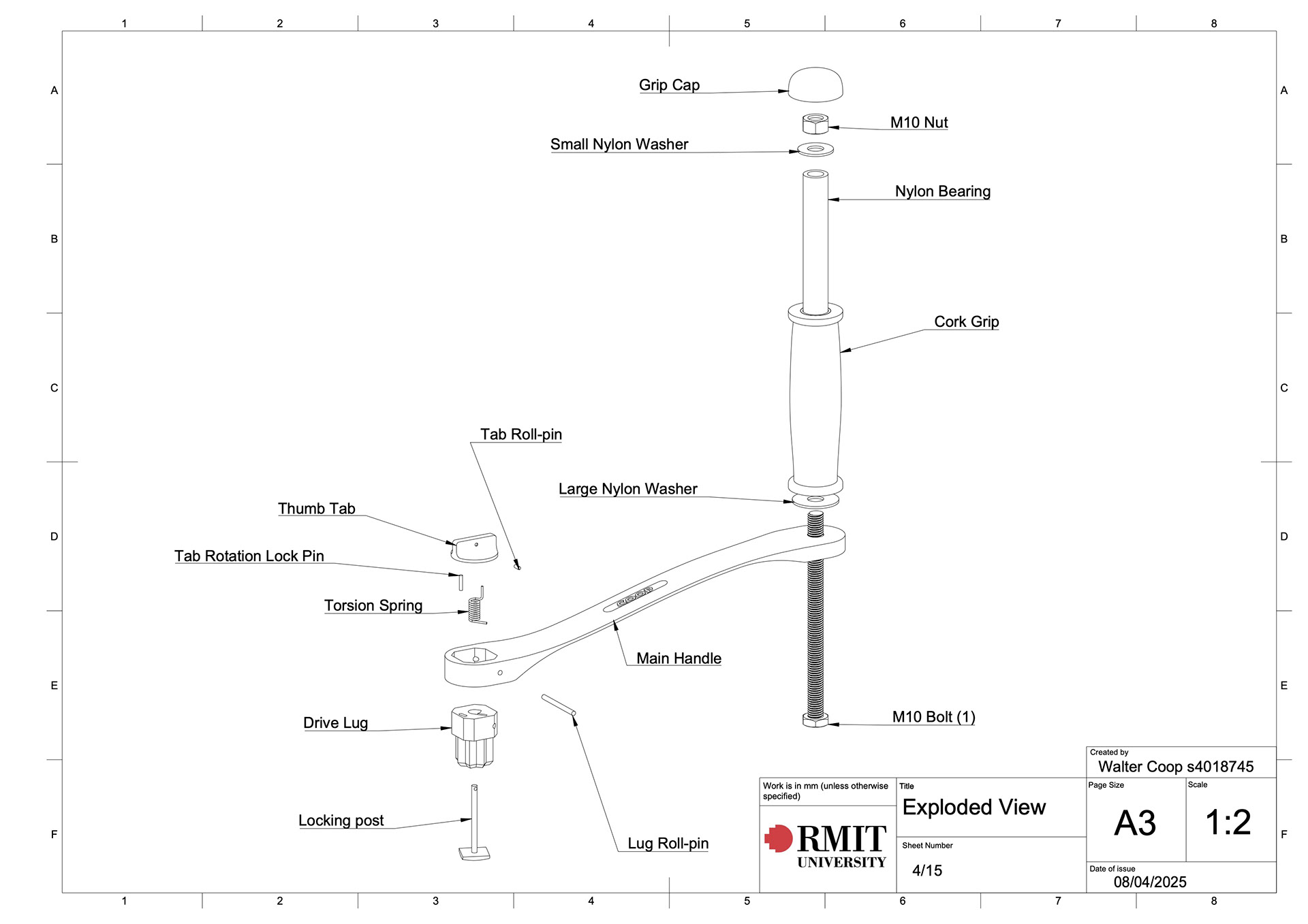

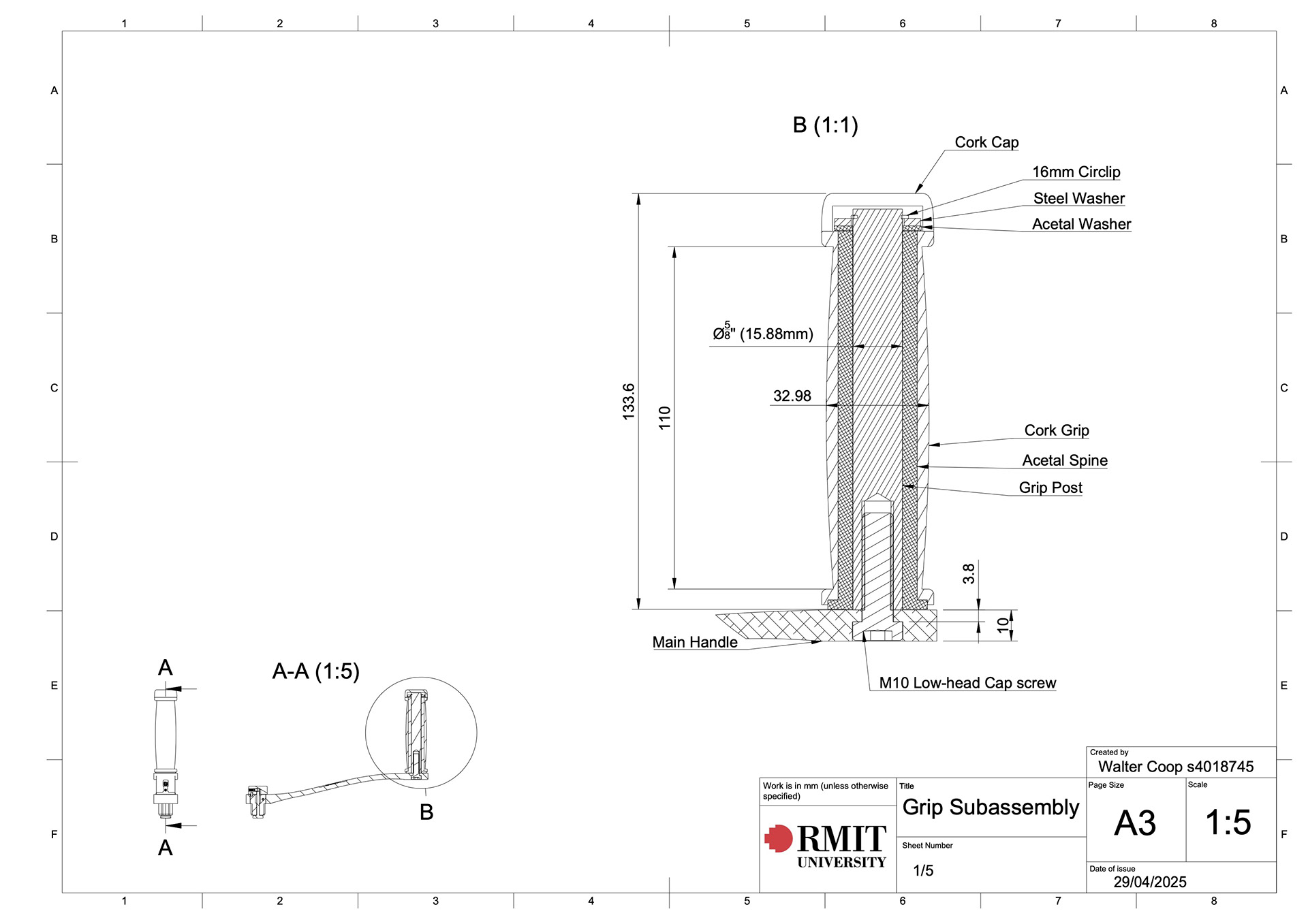

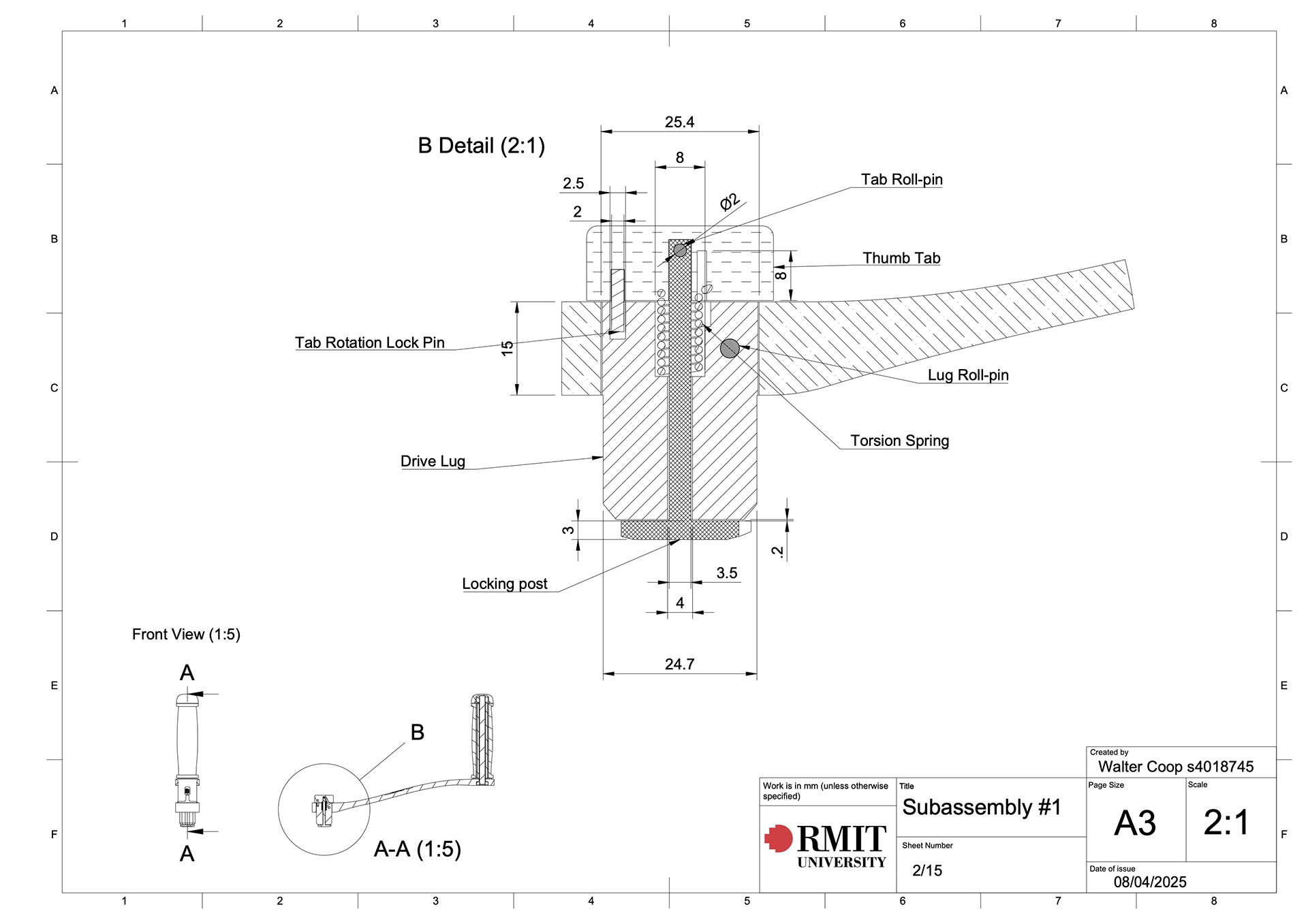

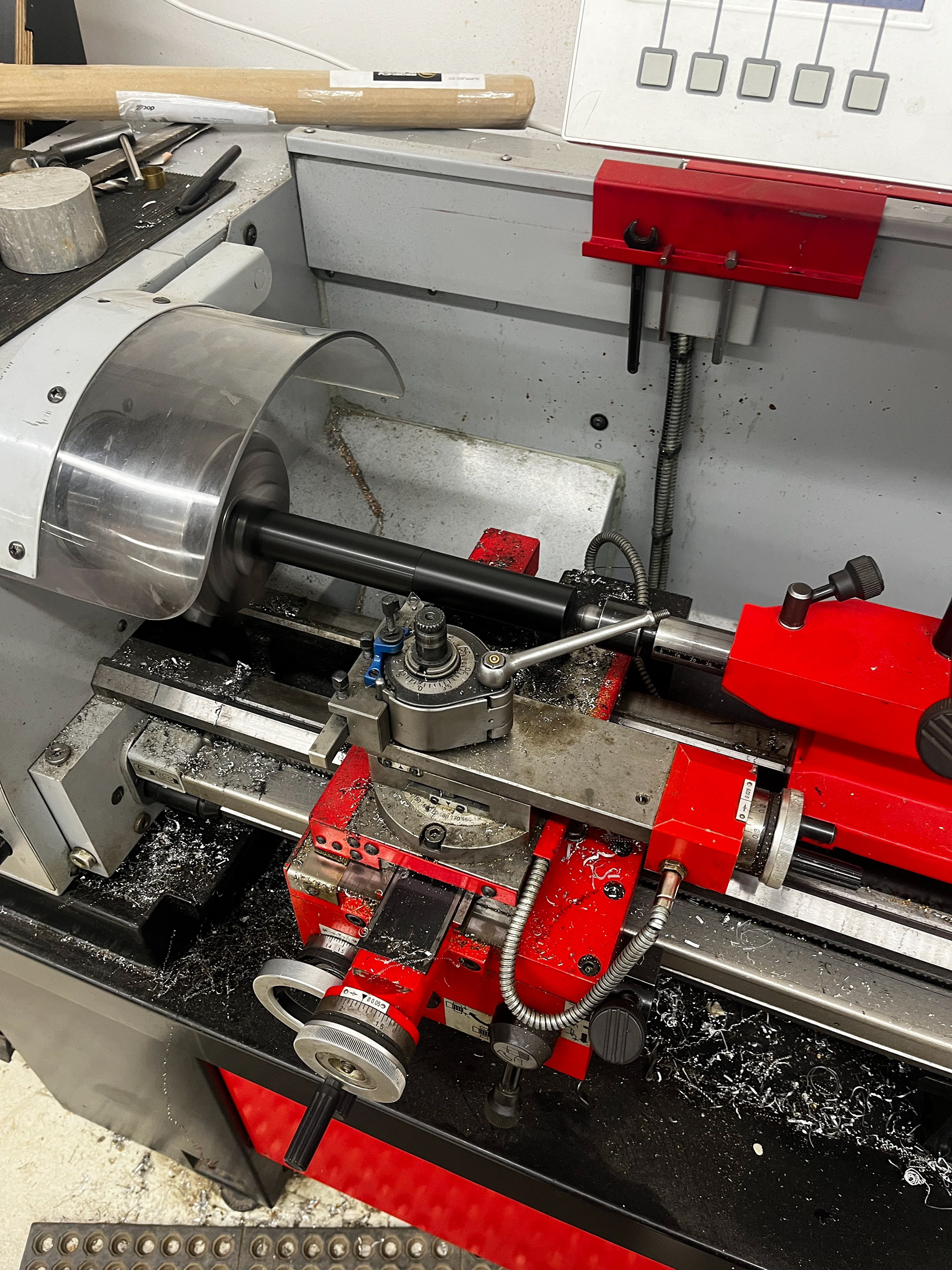

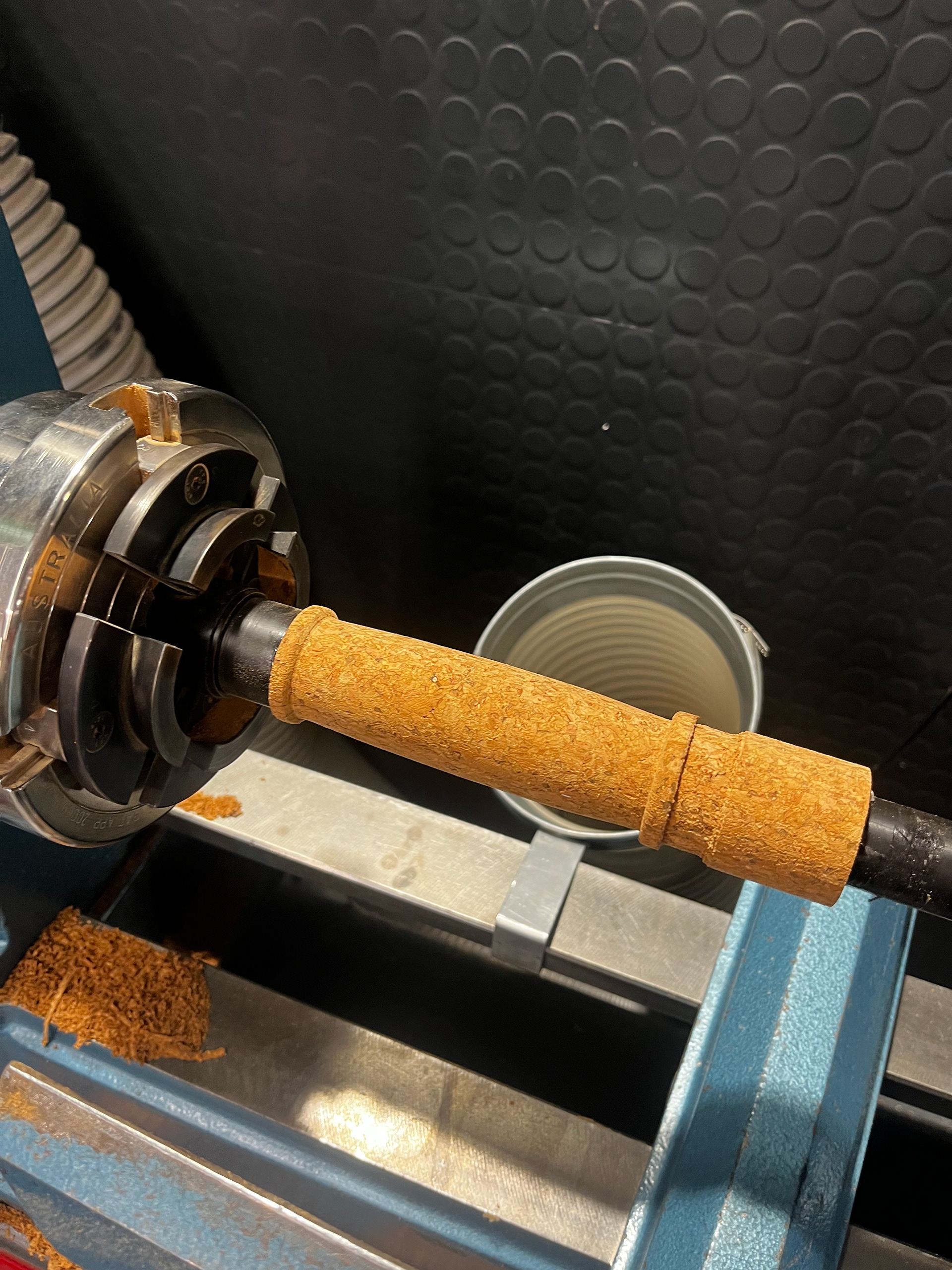

Through my own practical work and communication with experienced technicians, a prototype was fabricated using 3D printing, CNC machining, manual lathe work, and a variety of other processes.

A winch handle is an object central to the experience of a sailor. They are used, with a winch, to pull ropes under high load to hoist or otherwise adjust sails. A boat may have a handful on board, and they move from winch to winch, on and off, throughout a trip or race.

The working end of a winch handle is designed to wear out - to protect the winch's socket. With a traditional handle, this often means disposing the whole product as the 'lug' is cast into the shank as one component. Camber's design employs servicable, replacable lugs to prolong the valuable life of the object.

In a sport where many take pride in the elegance of their yacht, many winch handles fall short. A winch handle is typically a utilitarian object, with little thought put into visual design. This leaves another opportunity - to develop a product which lets sailors have pride over their gear.

In a sport where many take pride in the elegance of their yacht, many winch handles fall short. A winch handle is typically a utilitarian object, with little thought put into visual design. This leaves another opportunity - to develop a product which lets sailors have pride over their gear.

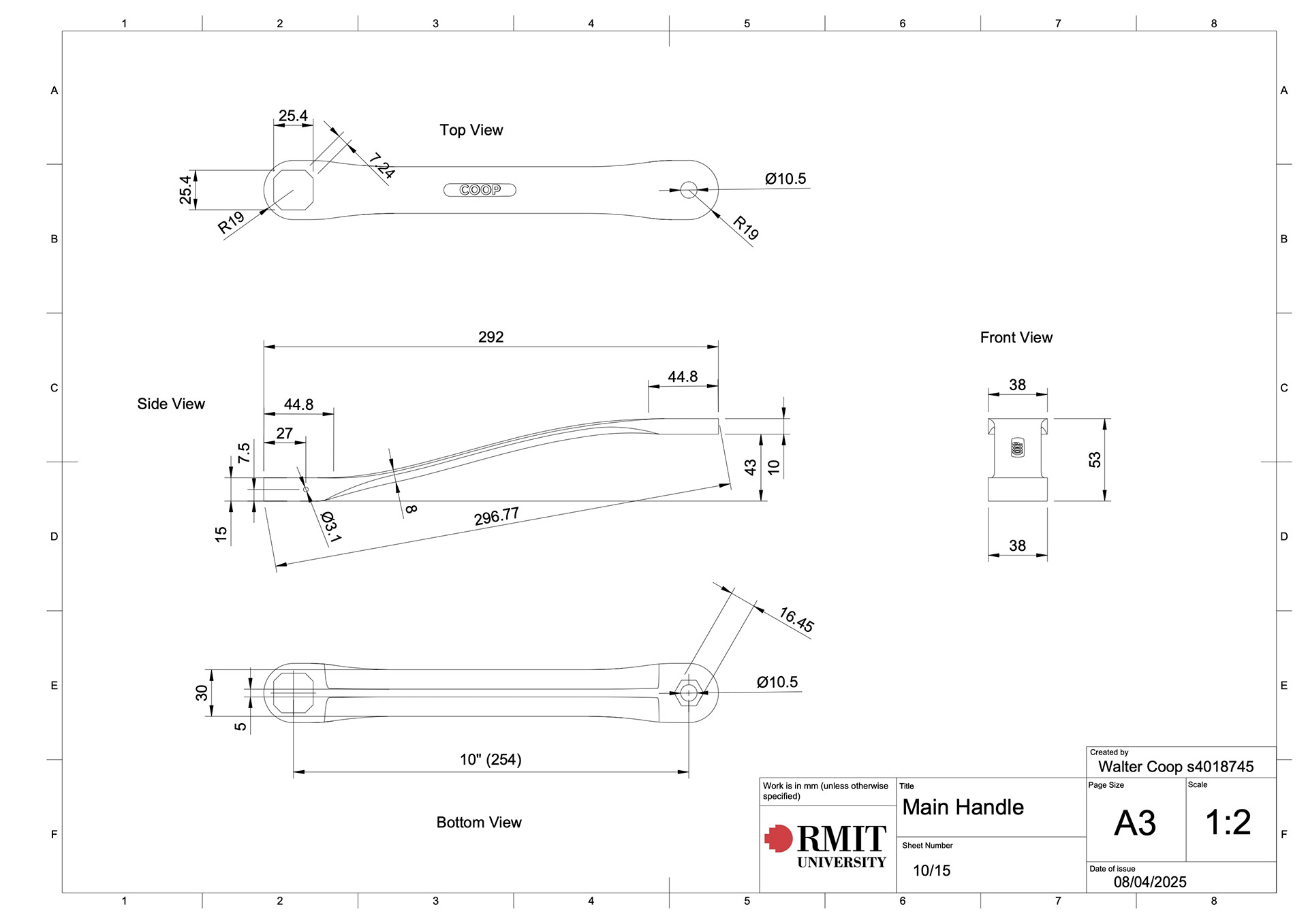

My focus for this project was largely focussed on design, and communication with technicians, rather than the fabrication itself. Although some manual processes were required, an extensive package of technical drawings and CAD files were prepared to communicate my designs to be manufactured, with many revisions made upon testing, changing manufacturing constraints and material sourcing.

Parts were machined from a variety of materials including:

6061 Aluminium

316 Stainless Steel

Solid Bronze

Solid Brass

Cast Acetal (POM)

Cork

Parts were machined from a variety of materials including:

6061 Aluminium

316 Stainless Steel

Solid Bronze

Solid Brass

Cast Acetal (POM)

Cork